Description

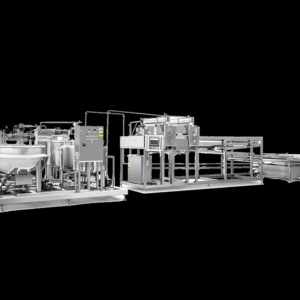

SANSO Potato Chips Processing Line – Process Description

After washing and peeling, potatoes are uniformly sliced using a precision slicing machine. The slices are then rinsed and blanched to preserve their natural color. Excess moisture is removed before frying to ensure crispiness. Finally, the chips undergo de-oiling, seasoning, and packaging in nitrogen-filled bags to maintain freshness.

Specifications

| Model | Capacity (Kg/h) | Power Consumption (Electric & Heating) | Power Consumption (Gas/Diesel & Heat) | Workshop Area Required (M²) |

|---|---|---|---|---|

| OSMA-50 (Semi-Automated) | 50 | 78 kW | 15 kW | 150 |

| OSMA-100 (Fully Automated) | 100 | 218 kW | 58 kW | 300 |

Process Flow

-

Washing & Peeling → 2. Slicing → 3. Rinsing → 4. Blanching → 5. Drying → 6. Frying & De-oiling → 7. Seasoning → 8. Packaging

Key Features

-

Compact & Efficient Design – Optimized layout for seamless production.

-

User-Friendly Operation – Easy to maintain and operate.

-

Premium Components – Equipped with internationally renowned electronic systems for reliability.

-

Energy-Saving Technology – High-efficiency combustion system ensures uniform heating, low energy consumption, and high output.

Equipment List

-

Raw Potato Conveyor

-

Peeling Machine

-

Selecting Conveyor

-

Feeding Conveyor

-

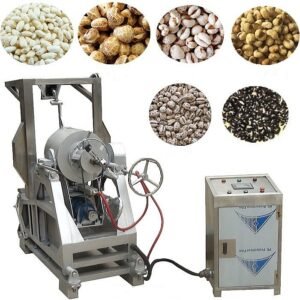

Slicing Machine

-

Washing Machine

-

Blanching Machine

-

Cooling Machine

-

Continuous Fryer

-

Vibrant De-oiling Machine

-

Single Drum Flavoring Machine

-

Cooling Machine

Reviews

There are no reviews yet.