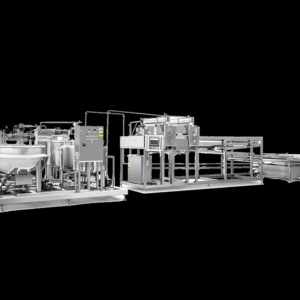

SANSO Corn Flakes Production Line

SANSO corn flakes (breakfast cereal) production line is designed to manufacture crispy, flavorful corn flakes and other grain-based breakfast cereals. These flakes are made from cornmeal and other grain powders, offering a satisfying crunch, excellent resistance to sogginess, and a rich, natural grain taste.

The production process includes mixing, extruding, flaking, drying, high-temperature baking, flavoring, and cooling. The final product can be enjoyed as a snack on its own or paired with milk or coffee for a wholesome breakfast.

Additionally, by adjusting molds and modifying the production process, this versatile line can produce various shapes of puffed snacks, such as rings, balls, flakes, stars, letters, and more.

SANSO Corn Flakes Production Line

In today’s fast-paced world, consumers demand breakfast options that are nutritious, convenient, and ready-to-eat. To meet this demand, food processing experts continuously innovate and optimize production solutions for high-quality breakfast cereals.

Corn Flakes Production Line Composition

The production line consists of the following key components:

Mixer – Blends raw materials uniformly.

Screw Hoister – Elevates materials for further processing.

Twin-Screw Extruder – Cooks and shapes the mixture under controlled heat and pressure.

Vibrating Feeder – Ensures consistent material flow.

Air Conveyor – Transports extruded product efficiently.

Flaking Machine – Rolls the mixture into thin flakes.

Dryer – Reduces moisture content for crispiness.

Hoister – Lifts flakes for additional processing.

High-Temperature Dryer – Further dehydrates and toasts the flakes.

Sugar Sprayer – Applies sweet coatings (if required).

Cooling Conveyor – Brings flakes to room temperature before packaging.

How the Corn Flakes Production Line Works

Mixing & Feeding – Raw materials and liquids are pre-mixed in precise proportions and fed continuously into the extrusion system.

Extrusion & Cooking – The twin-screw extruder applies thermomechanical energy, cooking the mixture at optimal temperatures. The product’s texture, shape, and expansion rate depend on factors like ingredient composition, moisture content, and extrusion temperature.

Flaking & Shaping – The cooked mixture is rolled into flakes using a flaking machine with temperature-controlled cylinders.

Drying & Toasting – Flakes pass through a multi-stage drying system to achieve the desired crispness and may undergo high-temperature toasting for enhanced flavor.

Cooling & Packaging – After cooling, the flakes are tempered, inspected, and prepared for packaging.

This fully automated production line ensures high efficiency, consistency, and customization, allowing manufacturers to produce various cereal shapes (flakes, rings, balls, etc.) by adjusting molds and processing parameters.

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.